Quala Santo Domingo

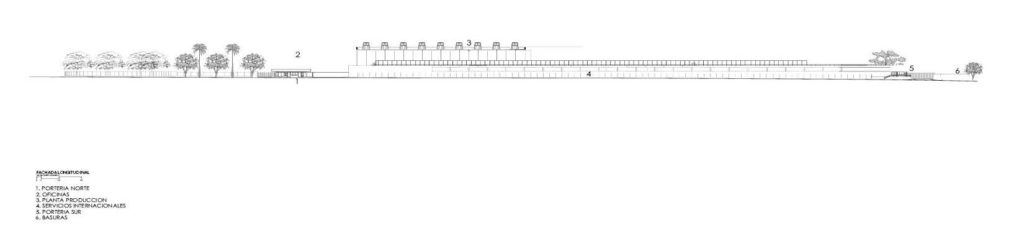

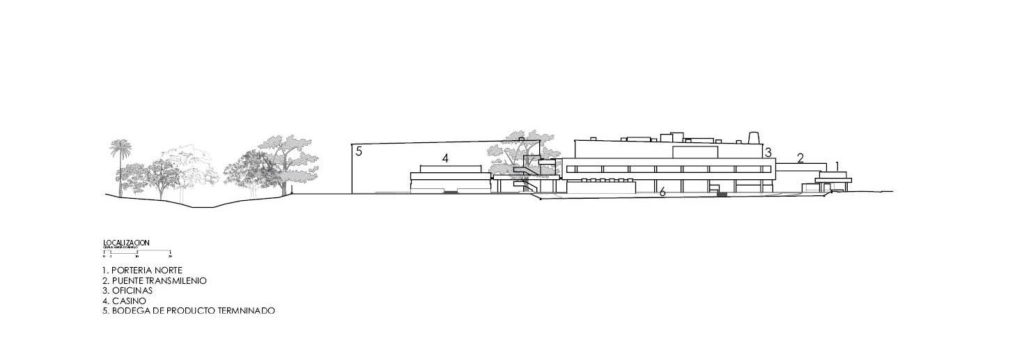

Santo Domingo, República Dominicana 2005 | Completed | 24.900 mt² | Industrial plant for Quala S.A. in the Dominican Republic

Design: Daniel Bermúdez Samper

Design Team: Evelyn Delgado, John Oscar Pinzón, Adolfo Sastre, Camilo Villegas, Ramón Bermúdez

Technical Systems Design: CCM – Contratistas Civiles y Mecánicos, S.A. – Pons Arquitectos

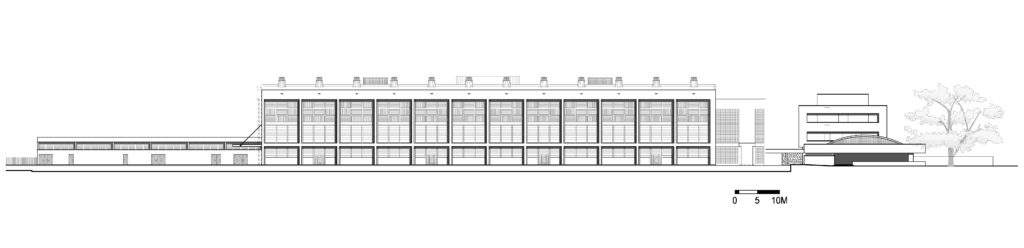

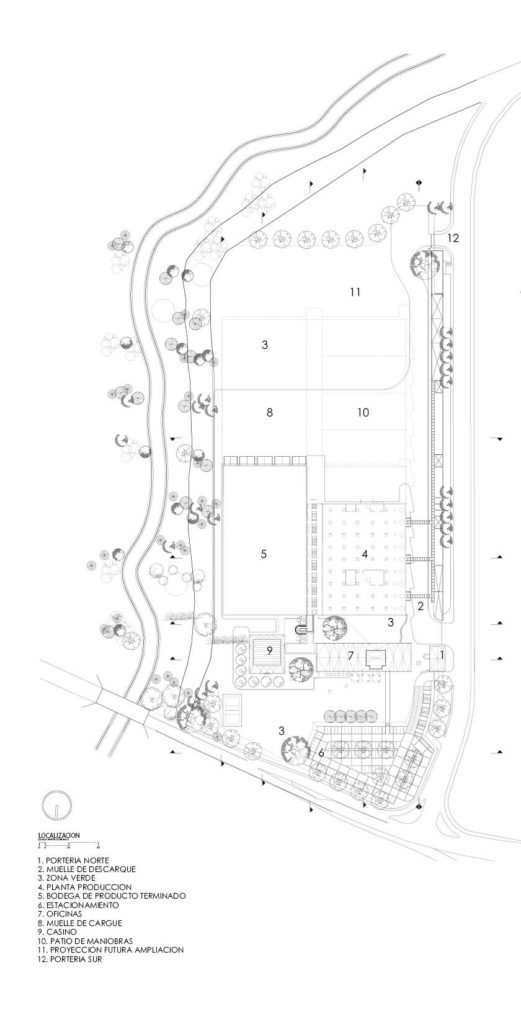

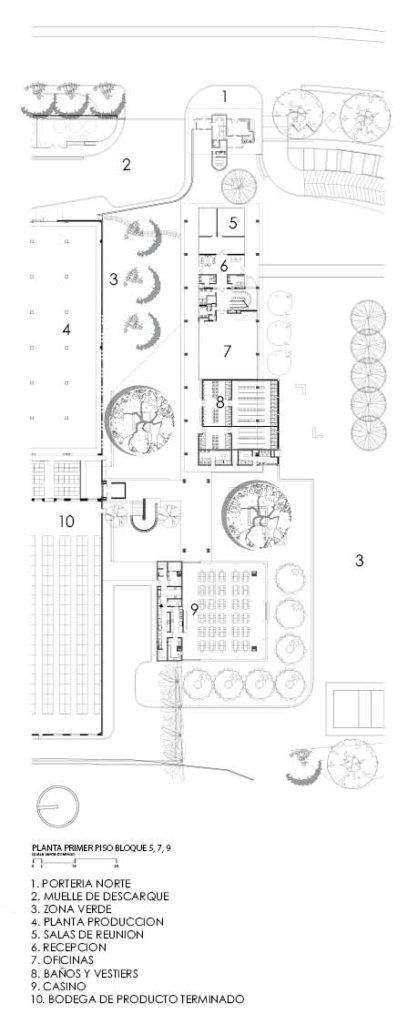

The Quala complex is located a few kilometers outside of Santo Domingo. The project includes a production plant, warehouses, laboratories, service areas and offices, occupying 24,900 m2 of floor area in total, along with a landscape design for the 6.5 hectares terrain.

The architecture of the industrial complex can be characterized as a reflection of the production process, with special attention paid to the employees´ wellbeing. Following a detailed analysis of the workers´ routines, from their arrival to the plant to their specific work stations, and of the products finding their way through the production chain up to shipment, the project seeks to provide the most favorable conditions both for the workers and the goods.

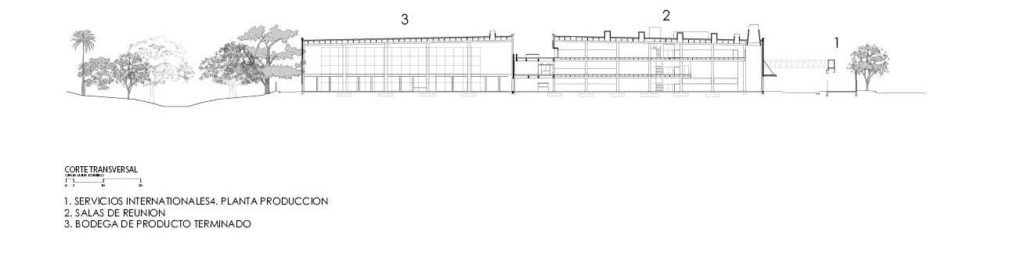

Situated in a tropical climate, the project is influenced by the particular conditions of its location and use, like the proximity of the Arroyo Porquero stream, the orientation of the site in relation to the sun and the winds, and the possibilities for future expansion. The understanding of these variables led to the arrangement of the different structures on the northern part of the terrain, making sure to leave a considerable area unbuilt to isolate the buildings from the highway. The offices and the cafeteria define the complex´ face towards the city, whereas the warehouses at the back take the maximum advantage of the prevailing winds coming from the east. Natural ventilation and continuous air renewal are the result of the bioclimatic strategies effectuated by ventilation chimneys and solar protection.

A separate building houses the maintenance and utility rooms for the industrial equipment, keeping excessive heat and energy away from the warehouses. Although the roof and façades provide protection from the intense climate -in a region frequently threatened by hurricanes- the use of natural elements helps to cool the interior spaces.

The main buildings are realized in white concrete, making use of two different construction systems. Where the office blocks and the cafeteria use conventional, in-situ cast concrete and wooden formwork, the warehouses were erected using a prefabricated tilt-up panel system, favoring flexibility, future extension and modification. The large concrete panels are cast on the ground and subsequently hoisted up to form a load-bearing structure of interlocking panels. This quick construction method allows for the mobility of panels to generate new distributions and combinations. It thereby facilitates future amplification, a crucial factor for the contracting company.